How Are Fullerenes Made – From the First Synthesis to the Present Time

How are fullerenes made? Are you interested in nanotechnology? If you want to get an insight into the process of production of fullerenes, you should continue reading.

First we will get back in time and get to know the basic facts of the very first lab synthesis that actually set the base for the commercial production.

Then we will concentrate on the modern production processes, specifically on the arc method. You will also know what materials and equipment are used in order to achieve the best result, which is a high quality nanomaterial.

How Are Fullerenes Made – Let’s Begin with the First Lab Synthesis

We will not go too deep in the history of fullerene discovery, but it is essential to know at least the basics of the very first synthesis as it started the whole new industry of nanomaterials production.

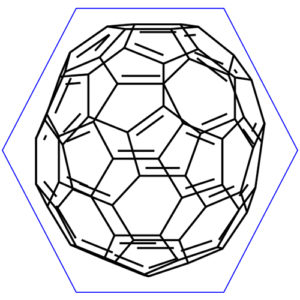

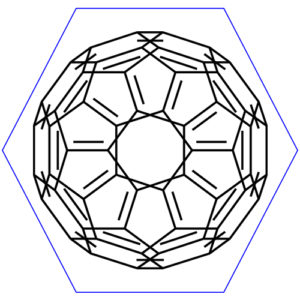

As you probably know the first fullerene molecule C₆₀ was discovered by Harry Kroto, Richard Smalley and Robert Curl, in 1985 at Rice University labs in Texas. However, the scientists failed to produce more of it, although they had been trying to do so for two years. That was kind of a frustrating situation. The one responsible for this task was Heath, who also assisted with the experiments that had led to the discovery of fullerenes. The thing is that he expected that if he mixed the material with benzene, it would concentrate into a sufficient amount of C₆₀. Apparently he was wrong.

Smalley expressed it this way: "After two years of looking at clear benzene solution, with no evidence of fullerenes, our conclusion was that perhaps someone else would isolate a bit of this someday.”

Well, he was right. Two scientists Donald Huffman and Wolfgang Kratschmer made it happen and again their success was a lucky coincidence.

The First Preparation of Fullerene

Huffman and Kratschmer were also working with the carbon clusters, but from completely different perspectives. In fact they were investigating the way how all small particles absorb the light. Originally their findings should have led to the better understanding of universe.

To do so, they have constructed a small machine that would make a lot of small particles.

How Did It Work?

Their device was very simple. It had two graphite rods. The rods were connected to the high electric current circuit and it worked in helium atmosphere. They used a hacksaw blade that worked as a spring to pull the rods together. In the places they touched carbon vaporized and formed lots of clusters. It was the soot. This black powdery substance is a mass of impure carbon, which is a result of incomplete burning of organic matter. That is how it all started.

- In the beginning they had only microscopic amounts, but after they changed the conditions, primarily the helium pressure, they suddenly could produce milligrams of it. And that was really something, because nobody had done that before.

- Then they already followed Smalley’s proposal and they started to research how molecule C₆₀ would absorb infrared light. That was certainly the right path

They published the results of their work in journal Nature in 1990. They not only proved C₆₀ existence, they also started its production.

Methods of Fullerene Production

- Laser evaporation technique – this is the method that was used by Kroto, Smalley and Curl. Their aim was to investigate the long linear carbon chains. For this purpose they used Smalley’s AP2 machine. This device allowed studying clusters of any element. How does it work? It fires pulsed laser beams at chemical elements. It reaches extremely high temperatures that are hotter than most of the surfaces of the stars. This way it vaporized the targeted element. Then the vapor cools down and forms into the clusters. The vapor is swept into the vacuum chamber by high pressure burst of gas. There the clusters condense. That is the time for the second laser pulse which ionizes the clusters and pushes them to the mass spectrometer, where they are analyzed. However, this method produces only microscopic amounts.

- Arc method – this is a common way how to produce fullerenes in gram-sized quantities in laboratories. Although it is not difficult to produce this amount of fullerenes it is quite challenging to purify them. Therefore this method consists of five stages.

The Five Stages of Modern Synthesis of Fullerenes

- Fullerenes are synthesized by the arc method from the fullerene-containing soot. By this process there are produced gram-sized quantities. In fact it is based on the Huffman Kratschmer method. There is struck an arc between two graphite electrodes in helium atmosphere (100~200 Torr). The device is surrounded by water to help cooling the soot. The resulting soot should contain between 10 – 15 % of soluble fullerenes.

- The extraction – there are two methods how to extract the fullerenes from the soot, the solvent and the sublimation method. The first one mentioned is the most common. It is used to dissolve the fullerenes in a suitable solvent such as benzene or toluene. This solvent also contains other impurities that can be separated from the solution by filtration. The sublimation method offers a suitable alternative. It is used in certain cases that are sensitive to contamination of solvent in the samples. How is it done? The raw soot is placed in a quarts tube and then the whole device is heated in the furnace. What happens next is that the raw arc soot is exposed and then kept at the highest temperature of 600 - 700°C. When finished the fullerenes sublimate from the soot. The soot then condenses in the colder part of the tube. C₇₀ and higher fullerenes have higher sublimation temperature than C₆₀ so it will condense closer to the soot.

- Separation (purification) – in order to achieve pure fullerene microcrystalline powder or solution, there has to be carried out a process of chemical purification, because the two previous stages may bring impurity molecules. This is done through sublimation and solvent method, the first one is based on the temperature gradients the second one on liquid chromatography.

- What follows next is the synthesis of derivatives. Usually by using the technique of organic synthesis.

- The last stage is for example the dispersion into the matrix and other post-processing

It is important to mention there is also the combustion method that is used in case of large scale industrial production. This way of preparation was discovered at Massachusetts Institute of Technology.

So What Are Fullerenes Made of?

To keep it absolutely simple, fullerenes are made of fullerene containing soot and the two most common method of their production is the arc and combustion method.

The nanotechnology is very fast-evolving science. Thanks to the research progress and also the advanced technology, you can buy Buckminsterfullerene for much lower prices than in the beginning of its production.

Now You Know How to Make Buckminsterfullerene

In fact this article has provided you with a complex overview of the past and present production of fullerenes.

Now you can recognize the two most common methods of their production and identify what are they made of. A great part of this article was devoted to the arc method, which was discussed in more elaborate way.

In the beginning 1mg of C₆₀ was sold for more than 1000$, luckily today the prices are much more affordable. Do you think fullerenes will be mass produced in a near future? What could be their estimated price per mg in ten years from now? Please share your opinion with us.